FENTON WELDING SERVICES

Welding

Providing AWS certified welders with years of experience. Processes include MIG, TIG, Stick,and Spot welding, on carbon steel, stainless steel, and aluminum.

Fabrication

Custom shop fabrication, including railing systems and stairs, commercial process equipment, storage tanks, metal resurfacing, coating systems, and high definition plasma cutting up to 1.5”.

Piping Systems

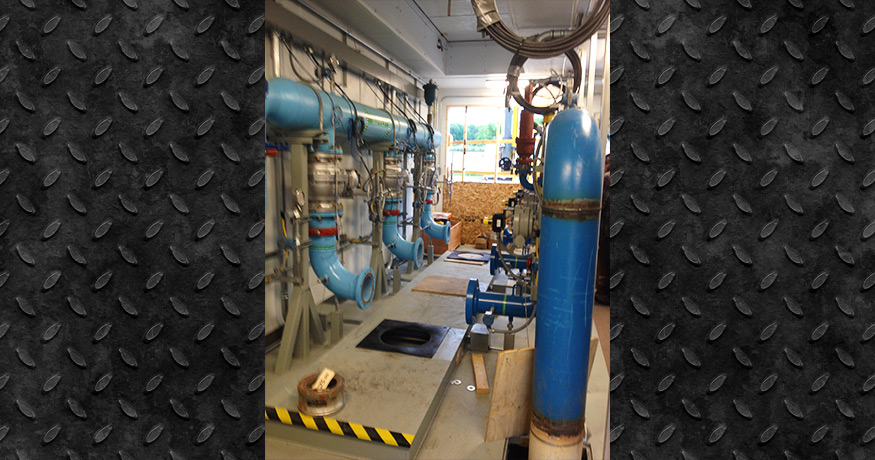

All forms of process piping, drainage systems, storm collection systems, working with all material from plastics to stainless steel.

Industrial Refrigeration

Ammonia piping installation, repair services, and pressure testing. Services include complete removal, and replacement of compressors, chillers, evaporators, cooling towers, etc.

Industrial Maintenance & Repair

General maintenance and repair services for commercial customers. Including, building renovations, catwalk systems, painting, carpentry, flooring, and plumbing. No job too big, or too small. Our team is on call 24/7 for emergency repairs.

Excavating Services

Commercial and residential excavating services. Land clearing, grading, trenching, repairing, and replacing water and sewer lines. Capable of handling larger projects, as well as complete site restoration (landscaping and seeding).

Drafting & Design

Ability to draft and design systems, and structures for customer approval using AutoCAD software.

Gas Field Solutions

On site welding services, equipment modifications, support systems, mechanical work, water source pump station installs and maintenance, heat trace/insulation, excavating and right-of-way (ROW) repairs.

WELDING PROJECTS

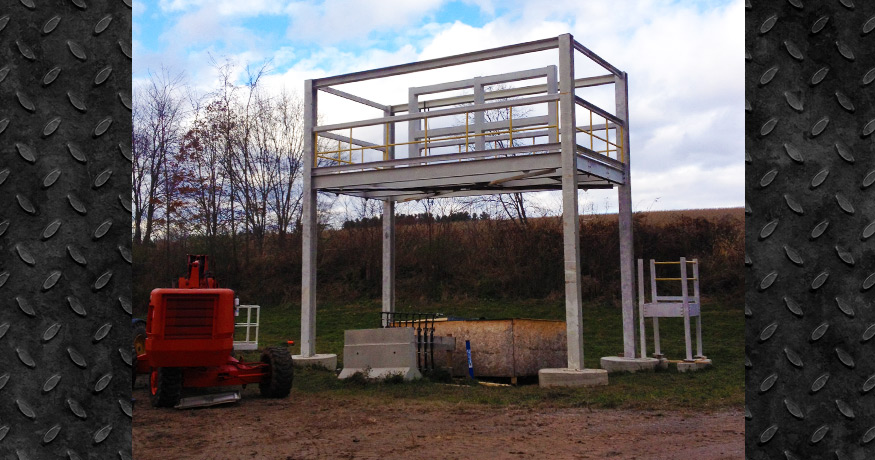

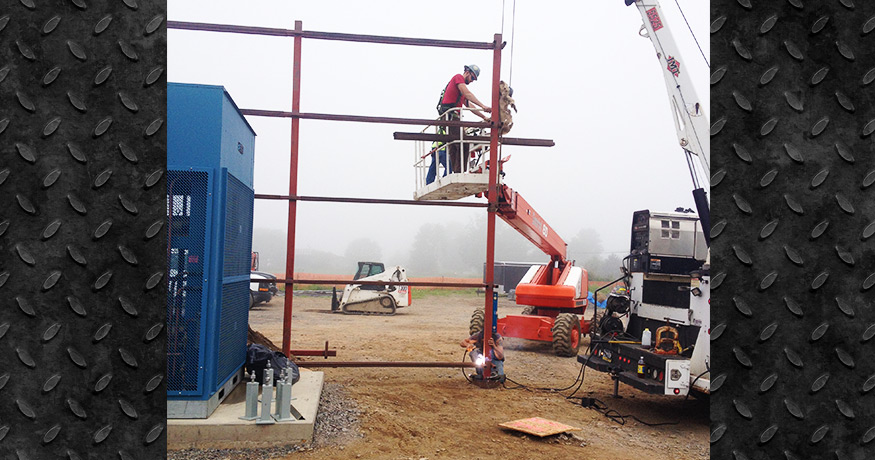

Installed a 1500HP Water Booster Pumping Station, and withdrawal MCC Tower. Performed all excavating, welding, and mechanical work for the project. Acted as general contractor with other qualified vendors. Performed all site work reclamation for DEP permit close out. Developed preventative maintenance procedures for our customer, and continue to provide support and repair services.

Our fleet of service and weld trucks allow us to make repairs at customer locations both quickly and cost effectively. We provide a variety of different repair services, and design solutions to keep our customers running efficiently. Pictured are some lease road gate repairs, removing and repairing an auger screw at a water solids removal site, as well as designing and installing a pipe support system at a compressor station to replace a failed design from a previous contractor.

Our 9,600 sqft. fabrication facility gives us the ability and spacing to house larger equipment, and facilitate multiple projects at one time. Our state of the art plasma table is capable of accurately cutting steel up to 1.5 inches thick, along with other equipment we use to provide precision cuts quickly, which ultimately reduces customer cost.

Worked with a local landfill on a heat loop project, where we installed and connected an underground piping system to recover wasted heat from an exhaust system. The exhaust heat now passes through a heat exchanger, where water is heated, transported to a centralized pump house, and ultimately provides heat and hot water for two other county facilities in close proximity to the landfill.

Currently we provide repair and maintenance services for 9 fresh water withdrawal sites, as well as 54 water impoundments for gas field water sources. Our services include pipe and valve installation and repair, winter operation solutions through insulation and heat trace, pump and compressor repairs, fabricating and installing spill buckets, water right-of-way repairs, and excavating services.

Fabricated and installed an intake pipe, and backwash piping system. Built a fish screen and debris containment filter on a rail assembly, with the ability to be raised for cleaning and inspection. We perform periodic inspections, and routine cleaning and maintenance at this particular site, as well as 9 other fresh water withdrawal sites, and 54 water impoundments for gas field water sourcing.

CERTIFICATIONS

Our employees possess a wide range of knowledge, years of experience, and certifications. Our welders are certified through the American Welding Society (AWS), and have earned specialized degrees from well recognized trade schools. All employees at Fenton Welding, LLC are at minimum 10 hour OSHA trained, and supervisors have earned their 30 hour OSHA credentials. In addition, all employees acquire their SafeLandUSA training for the US Onshore Exploration & Production Industry.

FENTON SAFETY

Fenton Welding, LLC is committed to the development, and continuous improvement of company Health, Safety, and Environmental policies and procedures. We have developed a culture in which HSE is equally important to all areas of our business, and we promote our employees to understand the important concepts of safe work practices while protecting our environment. It is our duty to our employees, their families, the environment, and our customers to ensure our personnel are provided with effective safety training, well maintained equipment, proper personal protective equipment, and awareness to harmful environmental factors.

Fenton Welding, LLC is a member of ISNetworld, a third party contractor safety compliance program. Our HSE programs, policies, and training requirements are verified with ISNetworld to ensure our employees are trained at the highest of standards, and ready for the job prior to arriving on location. In addition to continuous on the job training, all employees are trained internally in the following areas related to our line of work:

- Assured Equipment Grounding (GFCI)

- Benzene Awareness

- Bloodborne Pathogens

- Confined Space

- Cranes

- Disciplinary Program

- Electrical Safety

- Fall Protection

- Fire Protection

- First Aid

- General Waste Management

- Hand/Power Tool Safety

- Hazard Communication

- Incident/Accident Investigation Program

- Ladder Safety

- Lead Awareness

- Lockout/Tagout

- Noise Exposure/Hearing Conservation

- PPE

- Respiratory Protection

- Rigging and Material Handling

- Scaffold Safety

- Stop Work Authority (SWA)

- Subcontractor Management Plan

- Trenching/Shoring/Excavations

- Welding, Cutting, Hot Work

About Fenton

Fenton Welding, LLC is a family owned business, established in 1987 by the late Jack L. Fenton in Wyalusing, PA. Our company continues to grow steadily servicing one of the largest beef suppliers in the U.S., by providing structural welding, general construction, and plant maintenance services. While our footprint has been in industrial fabrication, we have expanded our services in the Marcellus Shale natural gas field since 2009. Fenton Welding was built by our hard working and talented employees, that have helped develop strong business relationships, deliver our services on time, and go beyond the expectations of our customers.

Our company offers a broad spectrum of services which includes structural welding and metal fabrication, complex industrial piping, general millwright services, excavating, drafting and design, and general commercial contracting. We are equipped to handle projects both large and small, and maintain close working relationships with our customers to ensure satisfaction. Our employees possess a wide range of knowledge, experience and certifications, including certifications from the American Welding Society (AWS), and specialized degrees from well recognized trade schools.

Our sister companies, Fenton Welding Transport, LLC and Fenton Service Center, LLC allow us to offer a full range of services to meet your needs. In addition to welding and contracting services, we offer equipment transportation including oversized loads, water and sand hauling, and truck repair and inspection services. We are well staffed with Class-A&B CDL drivers, AWS certified welders, licensed inspection mechanics, and project managers/engineers with years of experience in the construction and transportation industries.